From precision test fixtures to full automation systems, ICS delivers custom-engineered solutions for electronics, manufacturing, and industrial needs.

Serving Southeast Asia’s electronics and automation industry with turnkey engineering expertise.

ICS Engineering delivers complete production support — from design to deployment. With over a decade of experience and cross-industry expertise, we empower our clients with precision-built solutions and reliable engineering partnerships.

Since 2011, ICS Engineering & Servicing has delivered advanced solutions across test systems, automation, and custom engineering. From ICT and FCT fixtures to PLC-based control systems, cable assemblies, and turnkey production line integration — we are trusted by manufacturers seeking quality, reliability, and innovation.

From design to delivery, we provide full-service support — including prototyping, precision machining, assembly, and automation.

Our team combines technical expertise with hands-on experience in ICT, FCT, and industrial automation to solve real production challenges.

No two production lines are the same. We tailor every fixture, system, or component to your exact workflow and equipment needs.

Every solution is engineered for durability and high performance — built to withstand demanding production cycles and deliver long-term value.

Reliable RF shielding solutions designed to isolate signal interference during high-frequency testing. Customizable sizes available.

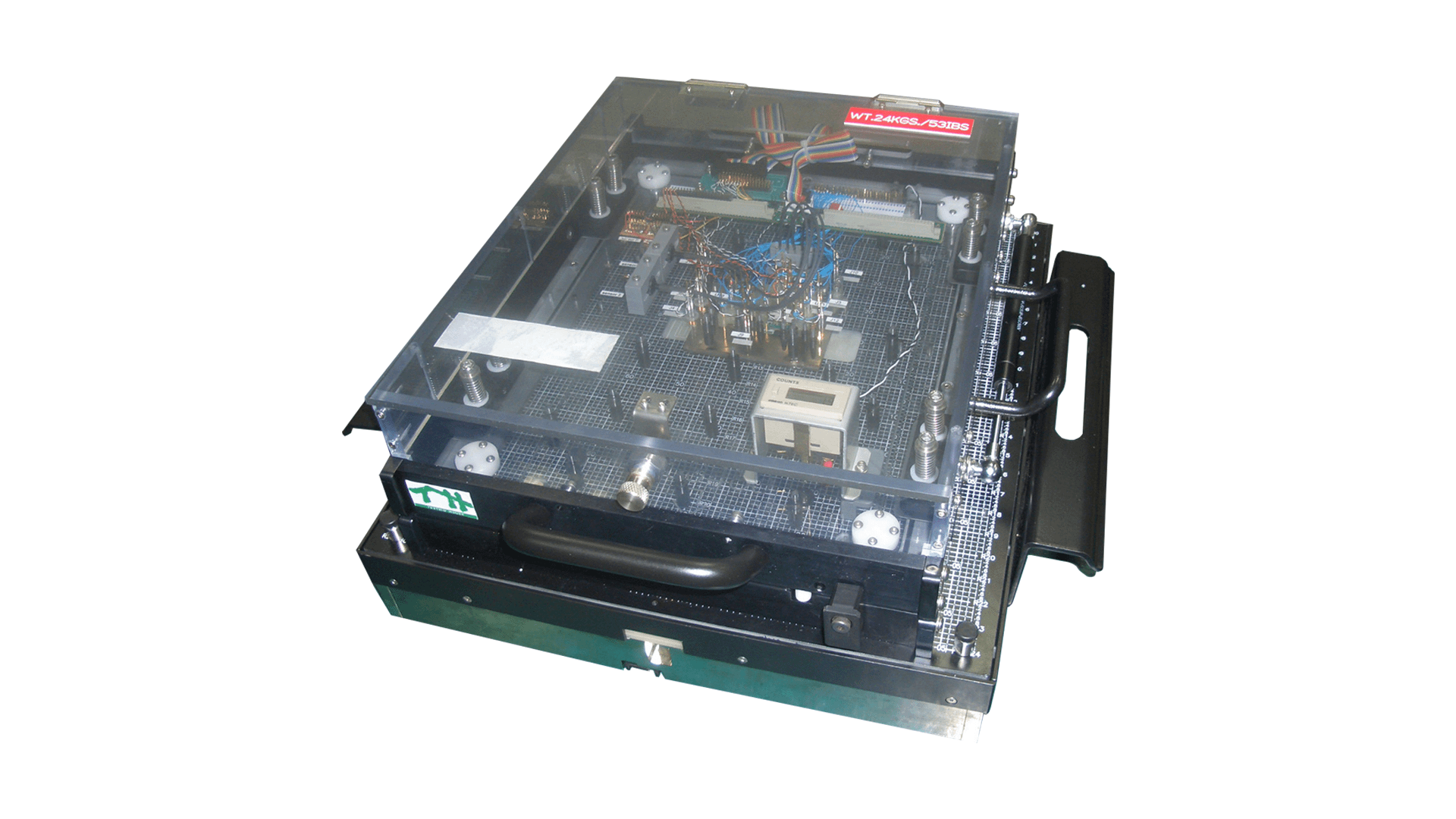

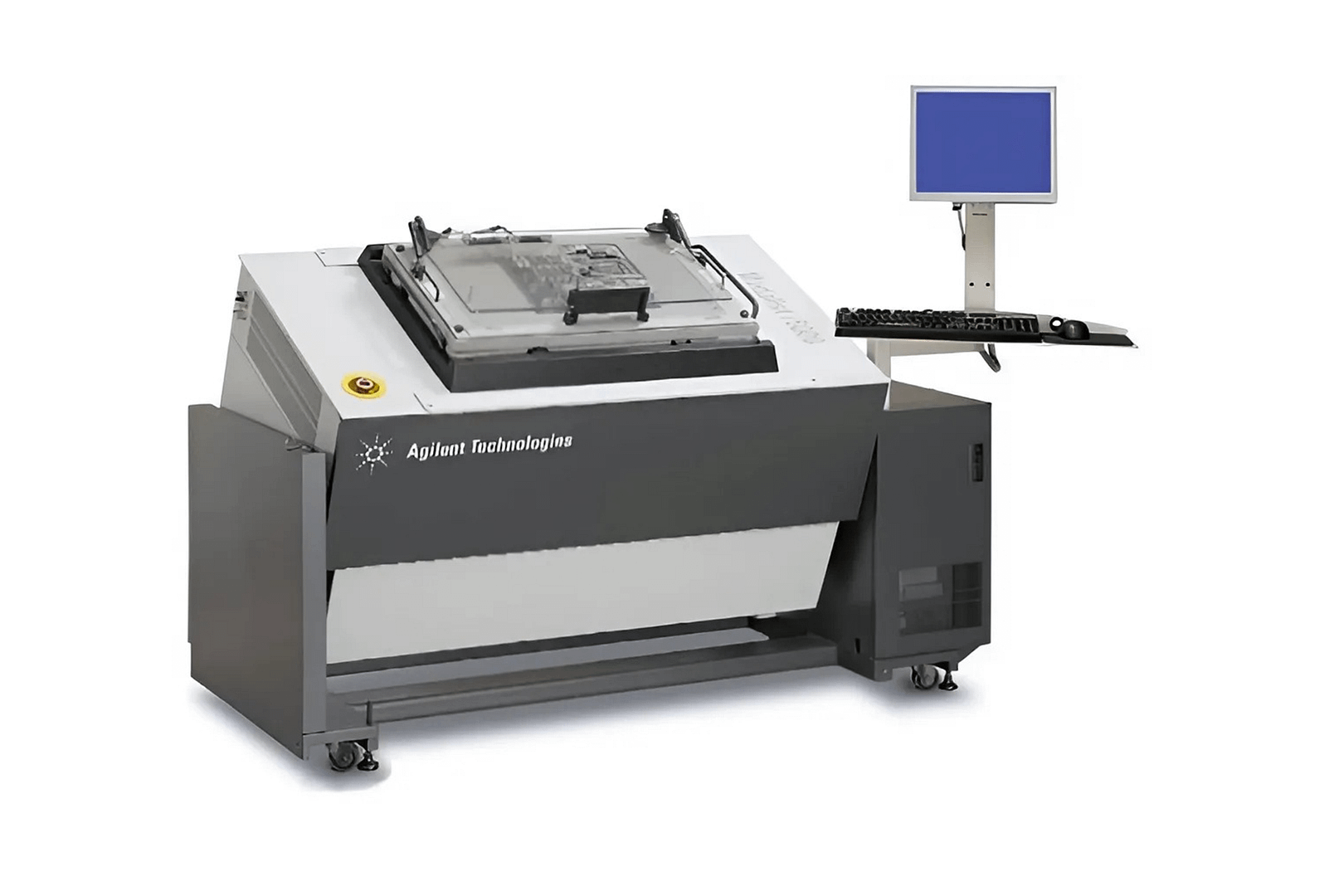

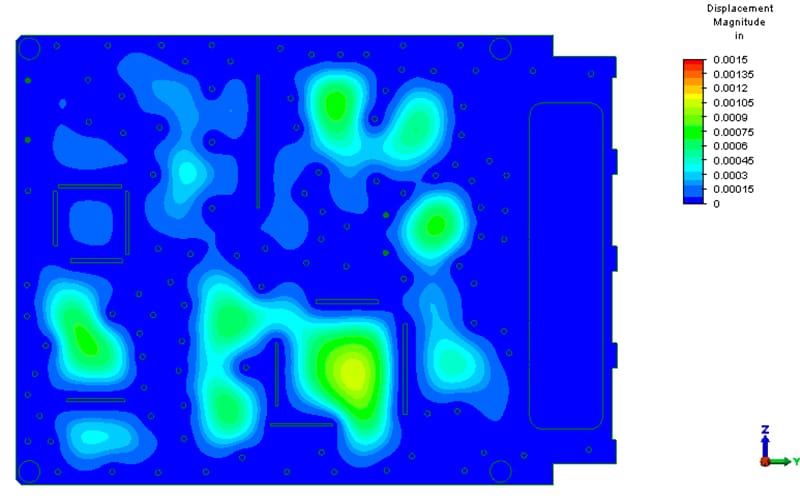

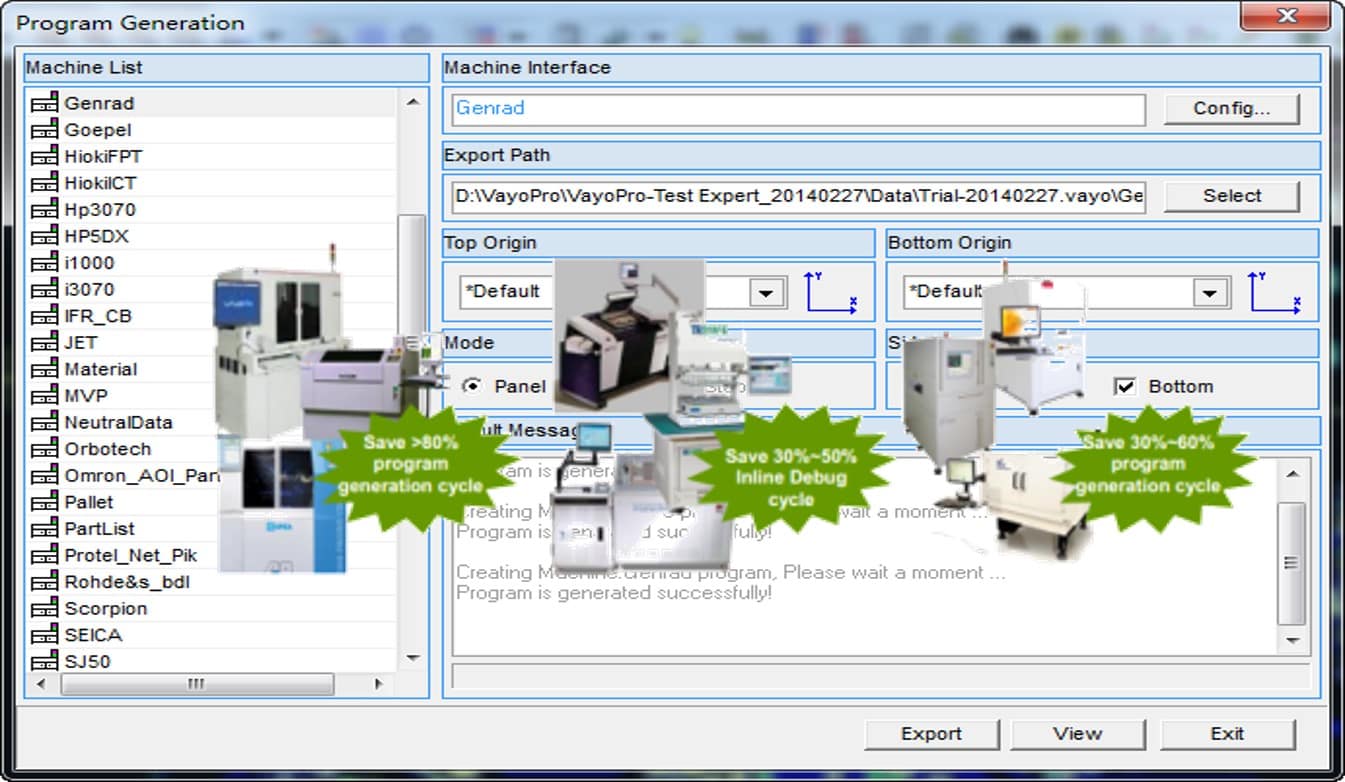

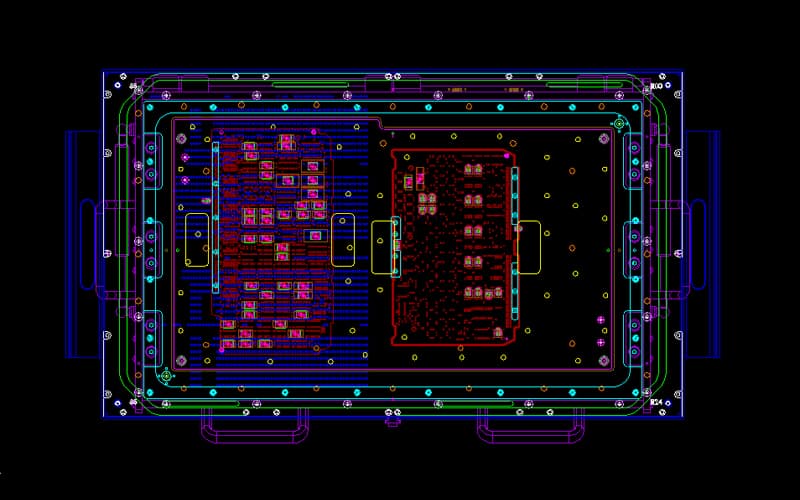

Precision in-circuit test fixtures for platforms like Agilent, Teradyne, TRI, and GenRad. Built for stability and repeatability.

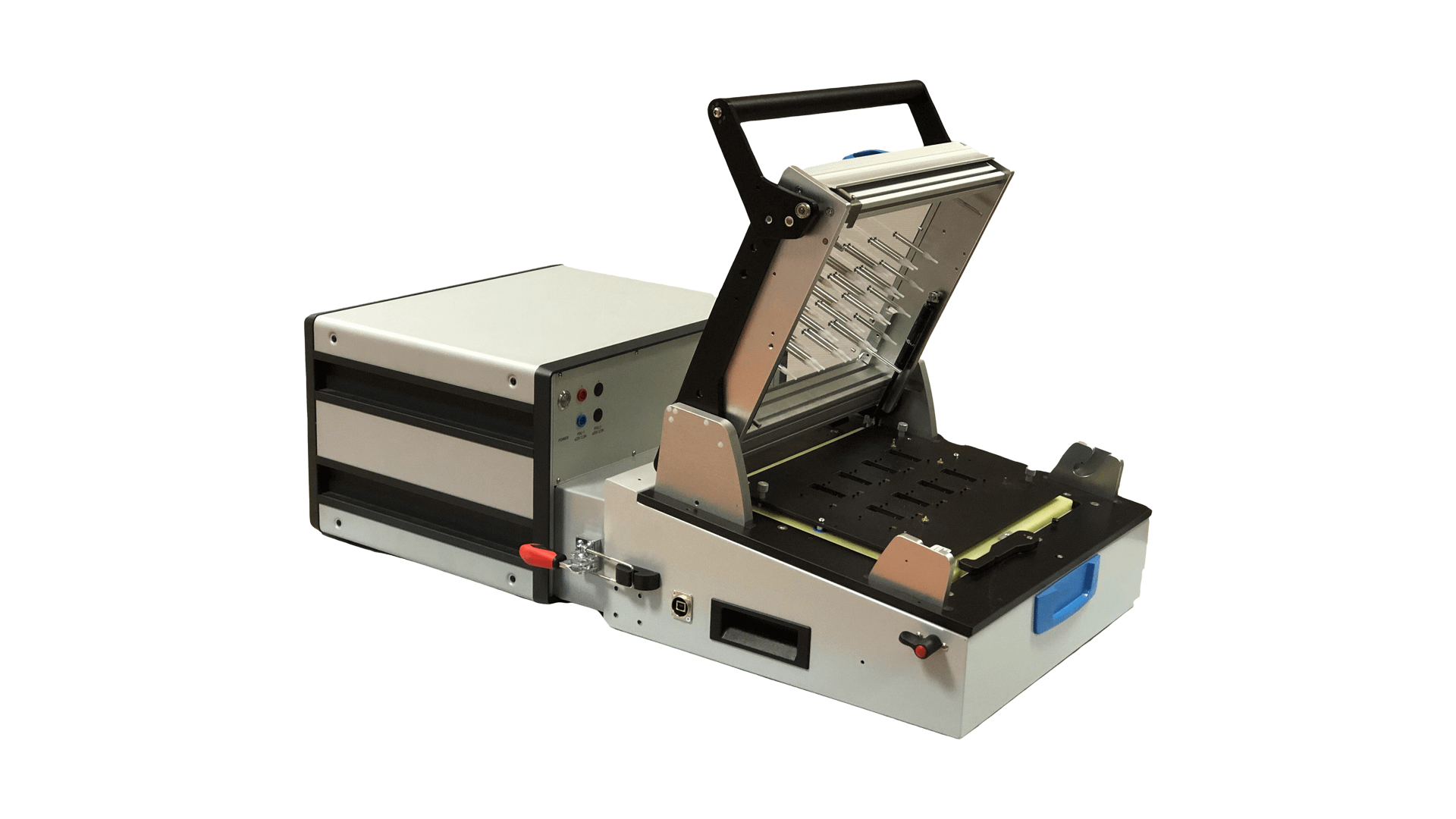

Semi and fully automated functional test fixtures for PCBA-level validation. Engineered to streamline end-of-line testing.

Custom-built test systems integrating software, fixtures, and automation. Tailored to your production flow requirements.

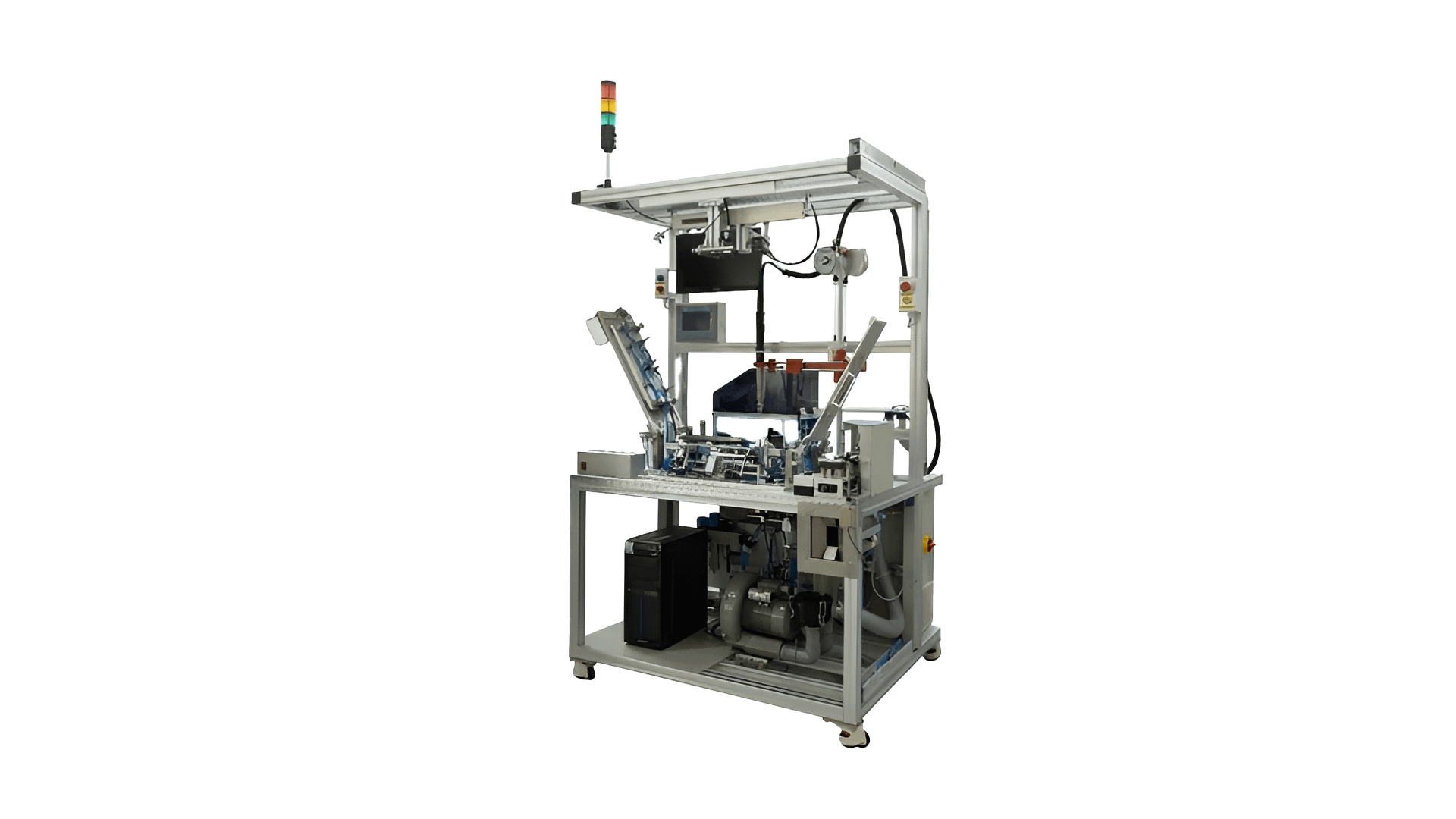

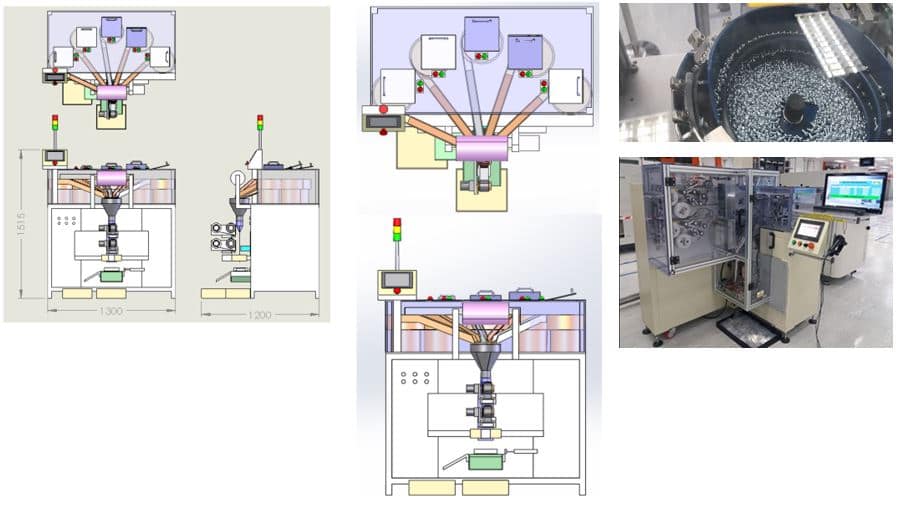

End-to-end automation designs incorporating PLC/PC control, sensors, and jigs. Ideal for scalable industrial integration.

All-in-one kits for fixture assembly and maintenance, including blocks, probes, receptacles, and brackets — ready for deployment.

Durable and heat-resistant BGA sockets designed for high-cycle life and easy replacement. Supports a wide range of packages.

Supporting components such as press mechanisms, holders, wiring, and interface parts for seamless test fixture performance.

Precision mechanical builds, including automated test fixtures, modular jigs, and integrated machine systems for production environments.

Development of custom-built continuity testers to validate pin-to-pin integrity in complex PCB layouts. Ideal for high-density assemblies and production QA.

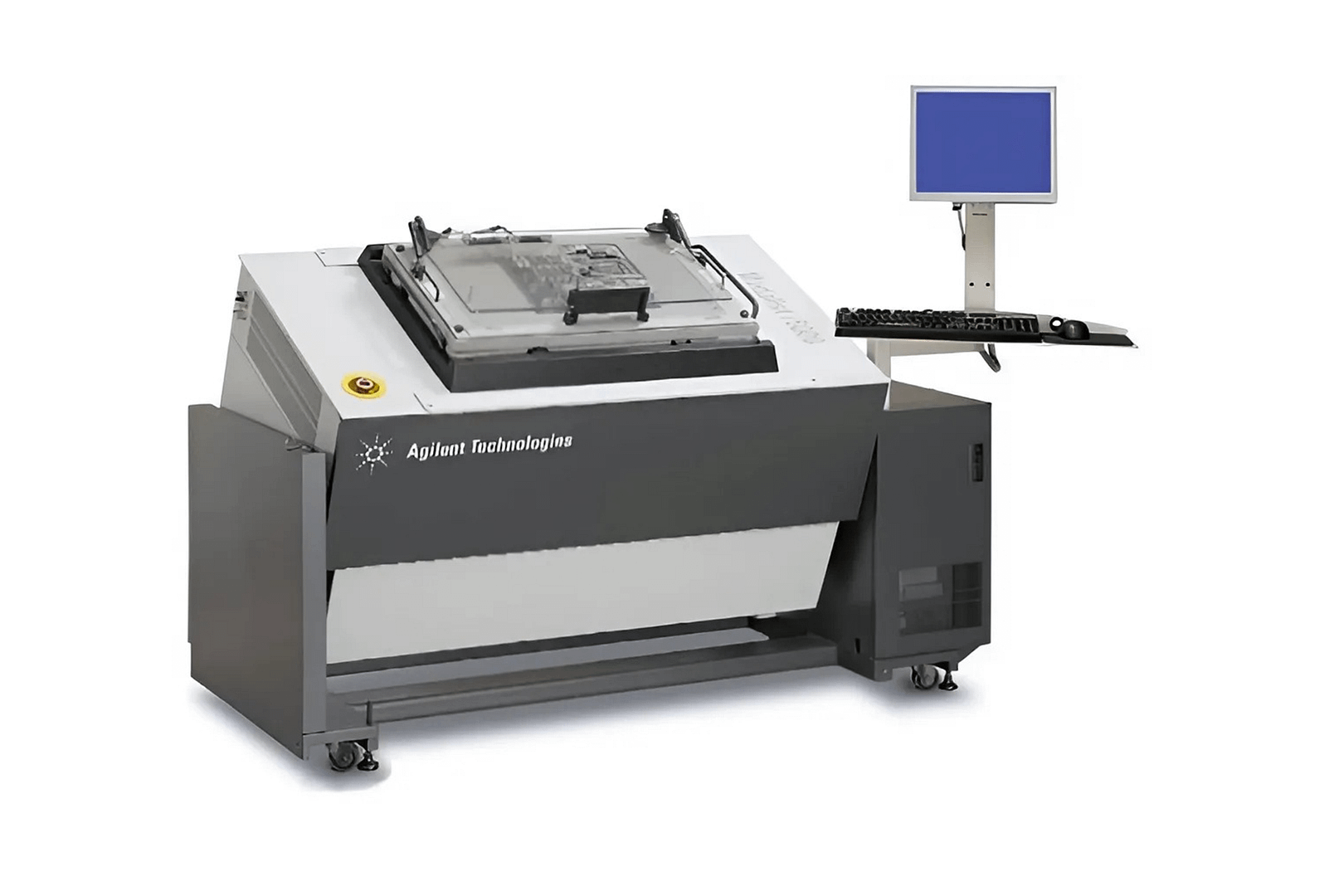

Stress and strain gauge testing services to evaluate PCB deformation during clamping and test cycles. Ensures board reliability and compliance.

Embedded test development using JTAG boundary-scan to verify circuit connectivity, detect shorts, and enhance test coverage for complex boards.

Full CAD/CAM support for fixture design, prototype validation, and high-precision part modeling — ensuring smooth manufacturing handoff.

End-to-end project design — from initial concept to full test architecture. Includes workflow planning, test coverage strategy, and solution integration.

Danny oversees both the test and automation teams at ICS, providing strategic leadership and engineering direction. He ensures end-to-end execution from fixture design to commissioning for complex, high-precision projects.

Email: danny@ics-eng.com

Phone: +65 9710 0806 / +6 012 710 1806

Jeffrey oversees FCT project workflows from initial scoping to delivery, managing engineering timelines, client communications, and commercial handovers.

Email: jeffrey.yap@ics-eng.com

Phone: +6 012 206 1459

Derrick brings deep expertise in embedded board testing, JTAG boundary scan, and system-level validation. He spearheads high-complexity test initiatives at ICS, optimizing access, accelerating debug cycles, and ensuring robust diagnostics across development and production.

Email: derrick.liew@ics-eng.com

Phone: +6 016 443 9629

We specialize in in-circuit test (ICT) and functional test (FCT) fixtures, shielding boxes, BGA sockets, custom automation systems, and complete test setups tailored to your production line.

Yes, we develop custom ICT and FCT fixtures for platforms like Agilent, Teradyne, TRI, and GenRad. Every fixture is engineered for compatibility, repeatability, and precision.

Our solutions are used in electronics manufacturing, semiconductors, telecommunications, automotive testing, and contract manufacturing.

Absolutely. From PLC/PC-based control systems to sensors and jigs, we deliver turnkey automation tailored to your workflow and production scale.

Lead times vary by complexity, but we typically deliver fixtures within 3–6 weeks and automation systems within 8–12 weeks after design approval.

Yes, we provide retrofit solutions and support for legacy platforms, including GenRad and older Agilent models, to help extend lifecycle value.

All our fixtures go through mechanical verification and electrical validation. We offer strain gauge testing, continuity checks, and JTAG Bscan integration to ensure reliability.

(For Construction-Related Inquiries)

From test fixtures to turnkey automation, ICS Engineering & Servicing Pte Ltd delivers solutions that power Southeast Asia’s electronics and manufacturing industry.